P.VCI 2D Bags

P.VCI 2D Bags

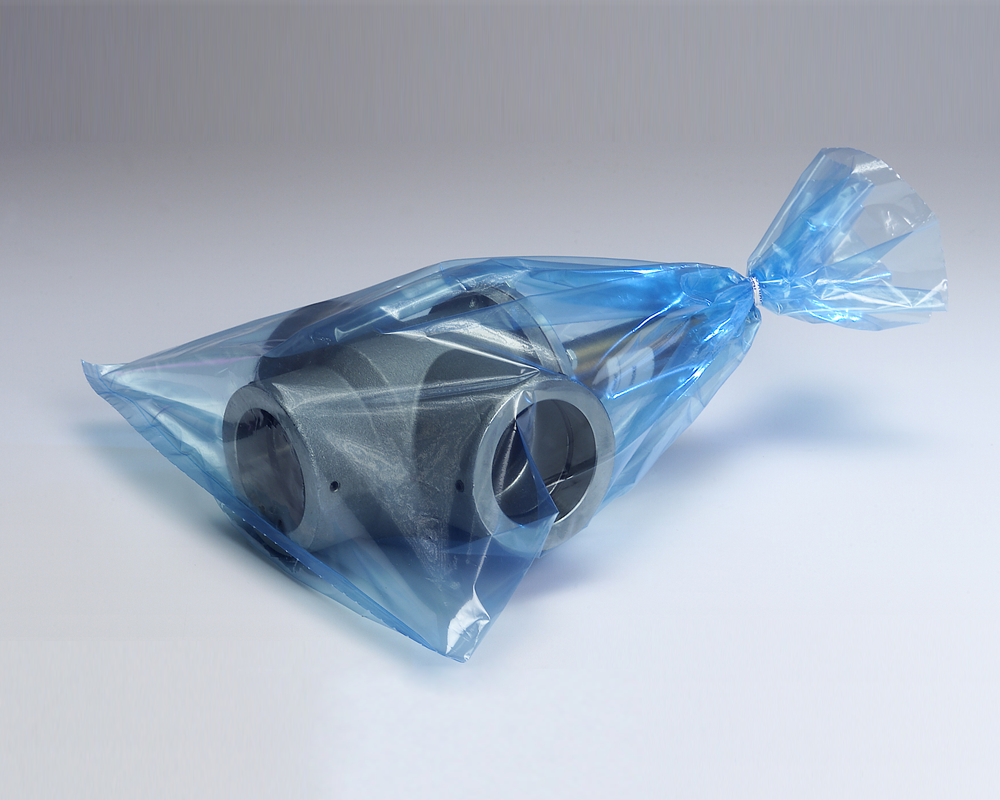

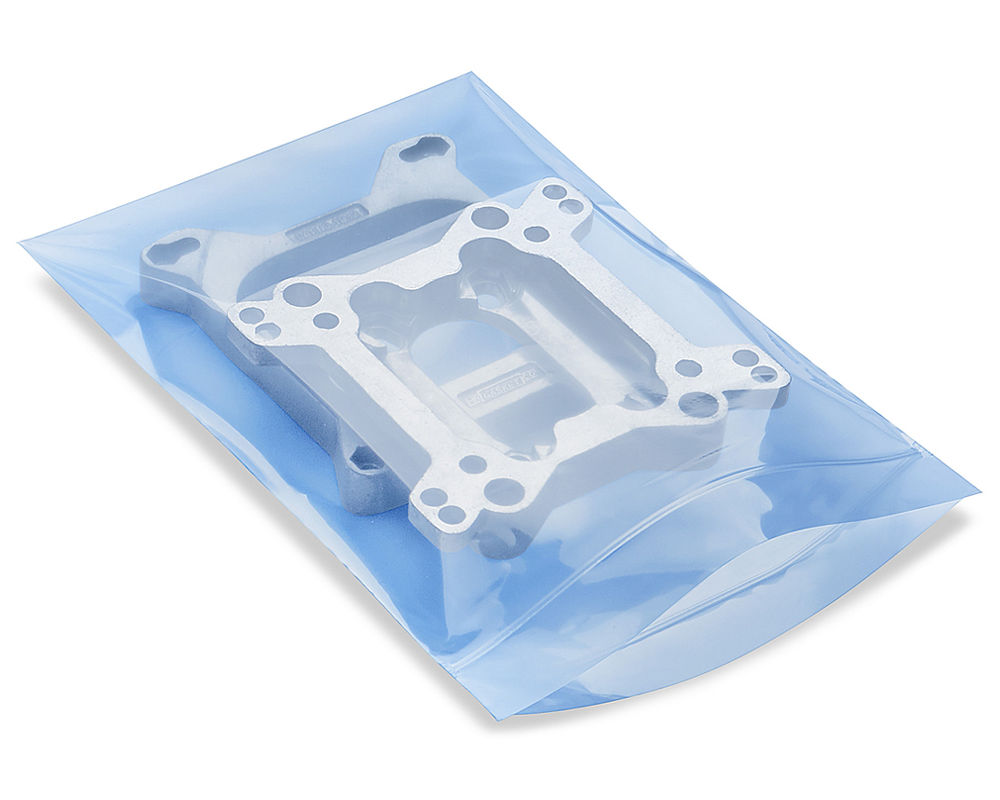

With P.VCI polyethylene bags, these rust preventative bags are perfect for packaging ferrous and non-ferrous metals – including carbon steel, chrome, stainless steel, copper, brass, aluminum, silver, silicon steel and galvanized steel – and require no additional packaging to stop and prevent the corrosion process. The P.VCI technology establishes a consistent barrier against moisture, and provides packaged parts with up to five years of corrosion-free storage.

As corrosion-inhibiting mediums, P.VCI Poly Bags encourage ease of use through the following features:

- Simple placement of metal parts into a bag

- Easy identification, inspection and inventory of metal parts in transparent bags

- Resistance to water, oil and grease

- Withstand temperatures from -60oF to +200oF

- Manufactured to your exact size specifications

- Economical and can be reused

- Extremely resistant to tears and punctures

We carry a wide selection of P.VCI bags for immediate shipment. Our P.VCI Poly Bags are recyclable, non-toxic, nitrite-free and heavy-metal-free, making them the only environmentally friendly choice for rust preventative bags.

How P.VCI Bags Works?

Rust Prevention Bags (P.VCI Bags) are coated with a corrosion-inhibiting chemical that transfers from the medium of the clear bag into the air through vaporization.

Because these chemicals work on a molecular level, the P.VCI technology completely adheres to the surface of the metal needing protection and creates a thin barrier against moisture, dust and other corrosion-causing contaminants.

The chemicals reach into crevices, cracks, nooks and other irregular shapes for comprehensive rust protection. The air inside the packaging environment becomes completely saturated with the corrosion-inhibiting vapors, keeping parts clean, dry, corrosion-free and ready to be used upon removing from the packaging.